-

Notifications

You must be signed in to change notification settings - Fork 30

Path Python Feature Details

A profile follows the boundaries of solid or a feature on a solid (eg a hole). The cutter moves to depth and then follows the edge at the radius of the cutter.

If the material cannot be cut in a single pass, a 'step-down' value indicates how far down the cutter descends on each pass until the final depth is reached.

A vertical feed rate indicates how fast the cutter plunges into the material

A horizontal feed rate indicates how fast the cutter moves forward.

The speed that the cutter spins at is called 'spindle speed'. The spindle can turn in either a forward or reverse direction. This can be represented as either two properties (speed and direction) or as a single float ranging from -n to +n.

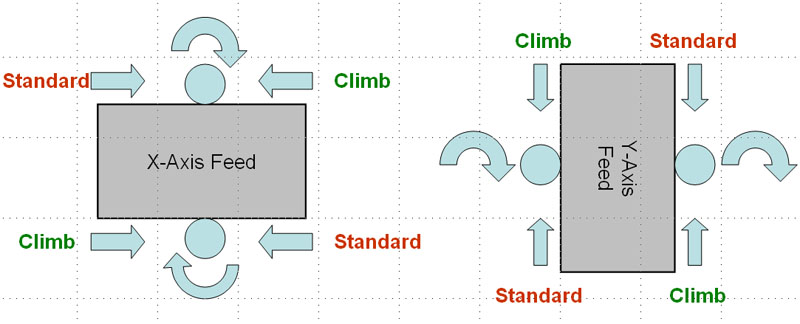

The direction that the cutter travels interacts with the direction it rotates. This is referred to as "climb" vs "conventional/standard" milling. The user should specify which method they prefer and the dirction of travel should be inferred.

Finishing Pass. Often a user will prefer to have numerous step-downs to rough-cut the profile and leave a small amount of material behind. A finishing pass is then done at full depth to remove the remaining material and produce a better surface finish. The user should be able to indicate that a finishing pass is desired and the amount of extra material to leave behind on the non-finishing passes.

Unlike a profile, a pocket uses the boundaries of a part feature to indicate the area to be cleared.

Just like a profile, the cutter may need to 'step down' a small amount on each pass until reaching the final depth.

Also like a profile, spindle speed, direction, vertical and horizontal feed rates, and climb/conventional milling must be indicated.

An area can be cleared in many different ways. The specific patterns and required properties is an area where extensive future development can be expected.

Drilling is a relatively simple operation but has some options the user will expect to set.

Like other operations, the user will want expect to set:

- The safe-height for traveling between drilling location.

- The spindle speed and direction.

- The vertical feed rate.

- The tool to use.

Specific to drilling, the user will want to indicate:

- The start depth of the drilling feed move.

- The final depth of the drilling operation.

- The 'peck depth' This is similar to a step-down. It is the distance to feed the drill before retracting to clear chips from the hole.

- The retract height.

- The dwell time. This is the time to dwell at the end of each feed cycle before retracting.

- A boolean value to indicate whether coolant should be turned on.

- A boolean value to indicate whether to retract at feed speed or rapid speed.